NTU lab to develop soft circuits for smart gloves, plant monitoring and less intrusive surgery

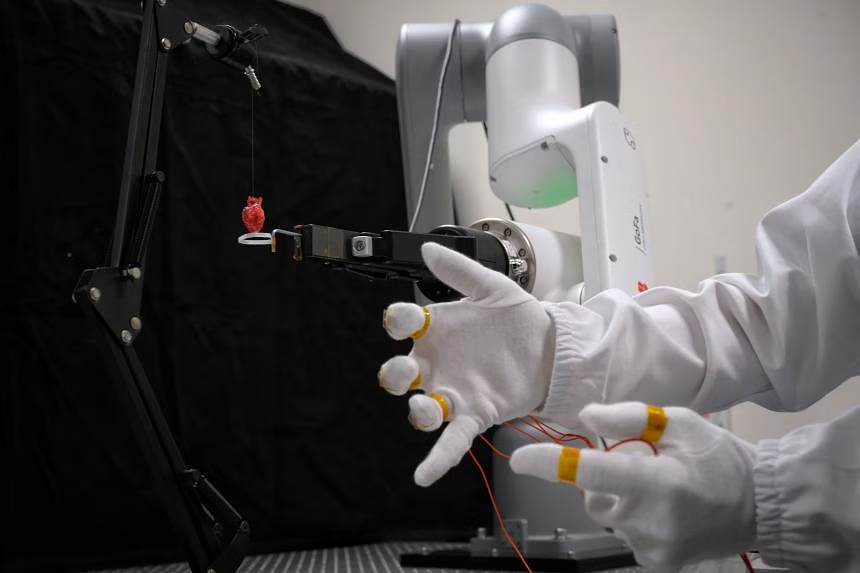

SINGAPORE – Telekinesis – the ability to shift objects with the mind which has been featured in films such as Star Wars and Carrie – may find a semblance of reality through robotics and ultra-precise motion trackers in gloves to operate machinery.

It has been made possible with soft, flexible circuits in the smart glove that enable accurate tracking of muscular movements, such as subtle twitches, surpassing external sensors found in today’s technology.

The new technology gives users greater precision over machines than via a controller, and can potentially allow those with physical limitations to handle machines remotely.

Such circuits are being developed at a new Nanyang Technological University (NTU) laboratory, which specialises in creating soft and ultra-thin electronics. These projects were presented to the media for the first time on Feb 14.

The lab, which opened in 2021, is supported by the National Research Foundation and Agency for Science, Technology and Research, among other organisations that support tech innovation.

The lab’s scientists are developing a wide range of early-stage prototypes to see which will help users more, and will work with its partners to deploy such circuits for real-world testing in the next two years, in the fields of environmental monitoring, health tech, robotics and other areas.

Traditional circuits are limiting for designers as they are rigid and typically flat, said Professor Chen Xiaodong, director of the lab at NTU’s School of Materials Science and Engineering.

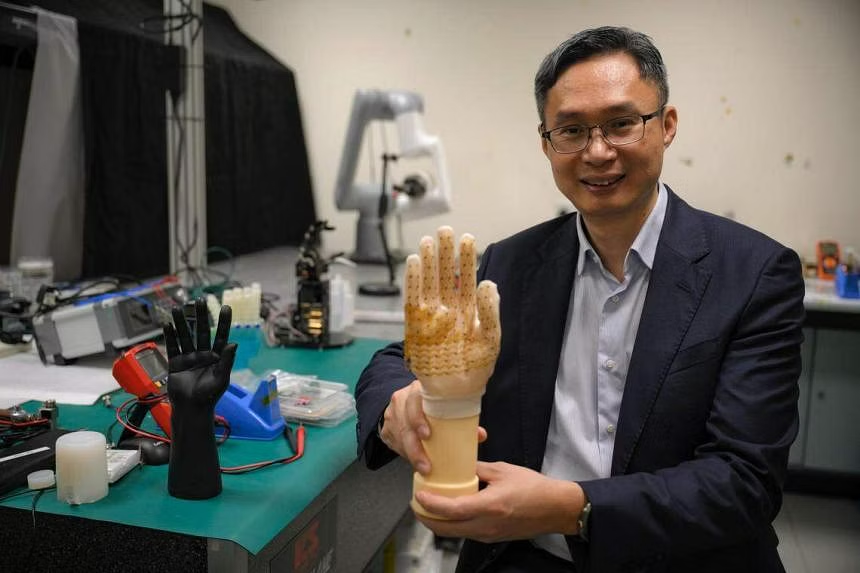

Professor Chen Xiaodong with a prototype of the smart glove, which is equipped with soft sensors. ST PHOTO: MARK CHEONG

“Many of today’s electronics are flat, like a smartphone or screen,” said Prof Chen.

“Humans and machines need a different shape, so we need to change how we make circuits.”

The media was shown a range of circuits developed by the lab, including some which are as thin as a tenth of a human hair, printed into a jelly-like layer.

Smart gloves are among the lab’s leading projects. The net-like structure of the glove’s circuit allows it to retain resistance, even when it is stretched. It can be wrapped around a hand to allow in-built sensors to make contact with key muscle points for accurate tracking, said Prof Chen.

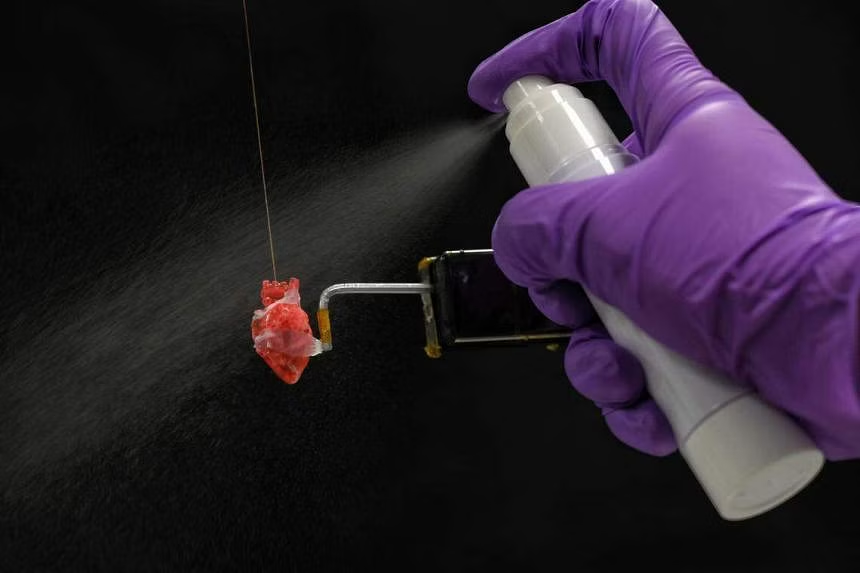

The technology offers a more comfortable option for sensors to monitor health or for individuals undergoing surgery. Biocompatible ribbons, with sensors printed on them, can be wrapped around soft tissues such as the heart or nerves, providing less-intrusive monitoring, Prof Chen said.

These ribbons, being flexible, help in implanting sensors and circuitry for other medical devices through keyhole surgery.

Biocompatible ribbons, with sensors printed on them, can be wrapped around soft tissues such as the heart or nerves, providing less-intrusive monitoring. ST PHOTO: MARK CHEONG

The lab’s prototype ribbon tightens around an object when it comes into contact with water – a process successfully conducted on lab mice.

The flexible circuit can be stuck onto plants to keep tabs on their health amid environmental changes, and to control their growth through electrical charges.

NTU joins other innovators in the quest for flexible electronics. Scientists at the National University of Singapore developed circuits that can stretch up to 22 times their original length without a significant drop in electrical conductivity, touted as a more comfortable and durable choice for wearables in rehabilitation.

Soft, flexible circuits in the smart glove enable the accurate tracking of muscular movements, such as subtle twitches. ST PHOTO: MARK CHEONG